Our Partner AUTOCOMP MANAGEMENT Sp. z o.o. is an international manufacturer and supplier of technologically advanced systems supporting training for the national defense sector and uniformed services as well as for rail, road and water transport. Autocomp is also the producer of dedicated specialized projects in industrial automation and naval equipment.

Autocomp has a huge number of completed motion simulation projects in its portfolio, but one of them deserves special attention: A comprehensive shooting simulator for the KTO Rosomak crew in the platoon version.

Comprehensive shooting simulator for Rosomak crew in platoon version is a unique and modern simulator designed for training of land army subunits equipped with Rosomak wheeled armored personnel carriers. The simulator allows to reproduce the real tactical and fire capabilities of the transporter during the execution of combat tasks. The Rosomak Wheeled Armored Vehicle simulator in the platoon version consists of eight cabins forming four manned simulation positions based on 6dof PS-6TM-1500 movement platforms ( driver’s compartment) and PS- 6TL-1500 commander’s and gunner’s compartments. Each position is built from a combat module mapping the turret with commander’s and gunner’s positions with a driver module mapping his compartment and an operator instructor’s position

Simulator’s Software

The simulator’s software uses artificial intelligence algorithms to simulate battlefield operations and the behavior of computer-generated virtual enemy forces, including the possibility of their effective impact on exercisers. The simulator provides a faithful realization of the full spectrum of realized tactical-firefighting sentences and directing fire by the crew of a Rosomak KTO platoon.

MOTION PLATFORMS

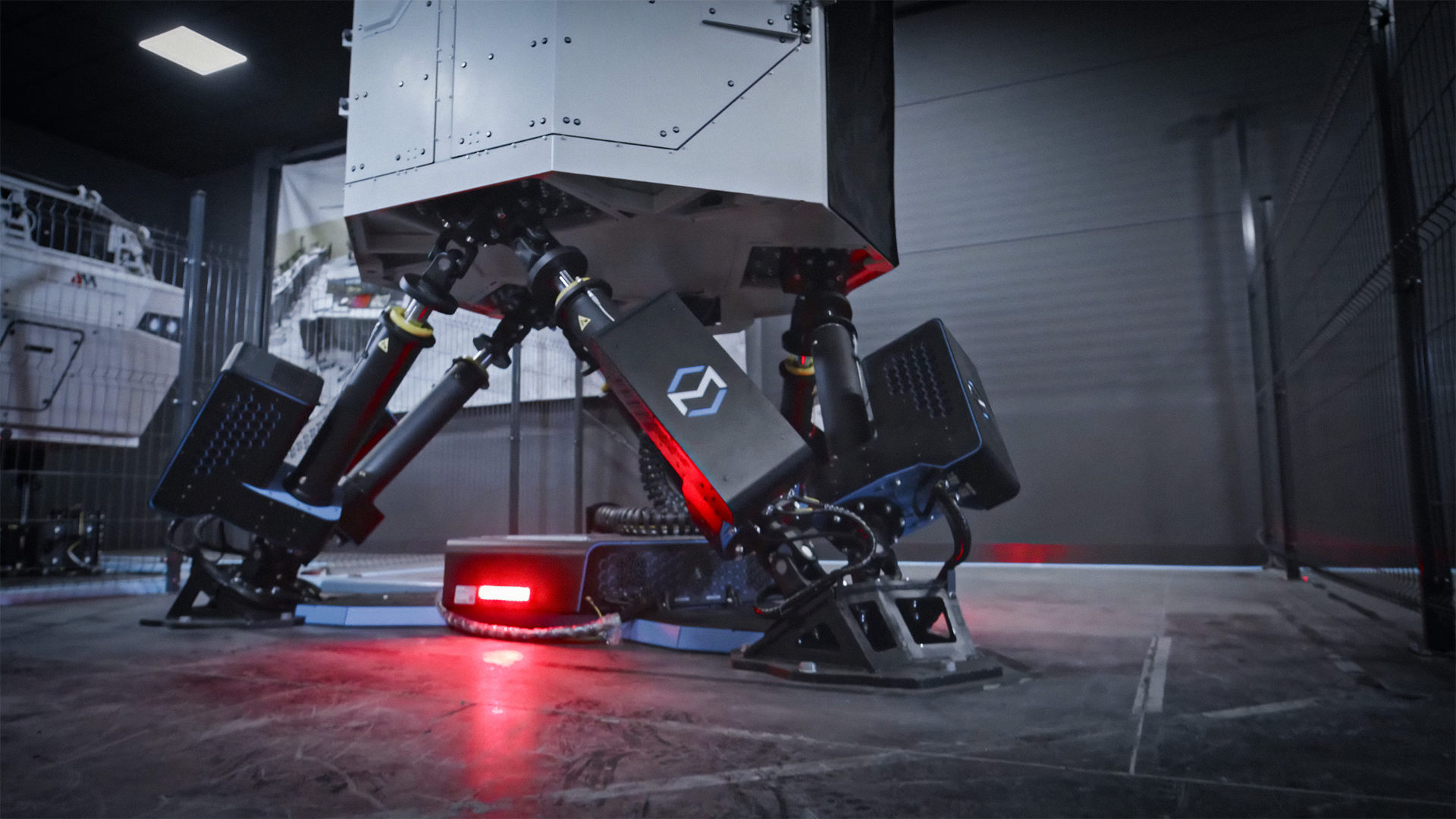

The PS-6TL-1500 product based on a Stewart platform, which provides the highest level of motion sensation and matches unique requirements of customers.

The PS-6TM-1500 motion platform is dedicated for 0.4G simulators, where the fully equipped cabin is mounting directly on upper frame. This motion system is chosen by customers, thanks to its ease of installation, super silent operation, good resistance to momentary overloads and reduced deployment time.